We use cookies to enhance your experience. By continuing to browse this site you agree to our use of cookies. More info.

H.C. Starck Solutions, suppliers of specialist metals, provide a range of technology metals to be used specifically in additive manufacturing (3D printing). Additive manufacturing allows highly complex and geometrical parts to be produced as a whole - meaning less parts are required to create device components and the assembly time is reduced. This technology is becoming popular across the board - from the medical industry to aerospace. 99.95% Bismuth Ingot

The H.C. Starck Group, headquartered in Munich, Germany, is a leading global supplier of technology metals, high-performance ceramics and thermal spray powders with decades of metallurgical and processing experience.

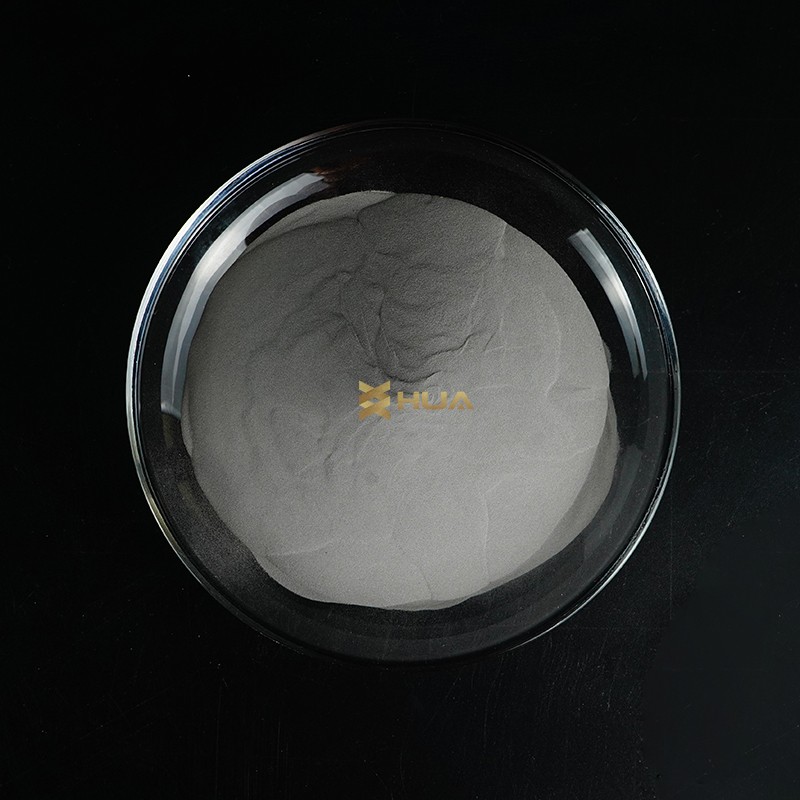

H.C. Starck produces high-alloyed AMPERSINT® metal powders of all major standard compositions, such as nickel- (Ni), cobalt- (Co) and iron- (Fe) based alloys, refractory metals and their alloys (W, Mo, Ta, Nb), as well as customized solutions with tailored chemistries and particle size distributions. Available from small to large scale batch sizes.

The perfectly spherical powder shape, excellent flow characteristics, low oxygen content and high reproducibility of H.C. Starck Surface Technology and Ceramic Powders AMPERSINT® powders ensure the repeatability, consistency and reliability of the Additive Manufacturing processes to achieve the optimum performance of Additive Manufacturing parts.

The Fabricated Products Division (FPR) of H.C. Starck Solutions, based in the U.S. with 6 manufacturing facilities on three continents, now offers spheroidized refractory metal powders and their alloys using state-of-the-art processing capabilities. These powders are designed from our core metals: molybdenum, niobium, tantalum and tungsten, in both pure and alloyed forms, with tailored chemistries and particle size distributions.

In addition, FPR develops innovative finished parts from refractory metals produced also using additive manufacturing processes.

H.C. Starck Solutions provides a range of different technology metals designed for use in additive manufacturing.

We knew Additive Manufacturing, also known as 3D printing, was going to be the technology of the future for manufacturing high-value components with complex geometric structures.

3D printing allows us the freedom to design and create objects in three-dimensions, leading to entirely new ways of manufacturing custom-made components and structural elements that are impossible to produce with conventional technologies.

With additive manufacturing, a product can be designed and a sample created in a fraction of the time compared to traditional manufacturing.

A single-piece component made from molybdenum or tungsten can be made without all the previously required manufacturing steps. So, production process steps such as the pressing and sintering of powders, thermo-mechanical processing, machining and assembly of components are eliminated, making it easier and faster to seamlessly deliver products to customers using this advanced additive manufacturing technology.

Suppliers, as an example, have demonstrated the ability to produce large titanium aerospace parts using additive manufacturing versus the traditional forging method. This demonstrates just how versatile this technology is and what types of complex components can be made.

Besides aerospace, there are many high-tech markets taking advantage of the technology including automotive, medical, chemical processing and energy, to name a few.

Additive manufacturing can be used to create complex, continuuous geometrical parts such as those found in aeroplane turbines. Image Credits: Nine_Tomorrows/shutterstock.com

Definitely, additive manufacturing has demonstrated the ability to eliminate assembly steps and make single-piece components that were previously produced from hundreds of individual parts.

For example, H.C. Starck Solutions' FPR has taken advantage of this potential to expand its product portfolio in lead-free collimators and anti-scatter grids for medical CT scanners, SPECT and gamma cameras.

We are targeting technically advanced applications in industries like medical and industrial imaging, nuclear and thermo-nuclear energy, and various aerospace and defense related applications that will be the first to benefit from H.C. Starck Solutions’ FPR additive manufacturing technology.

We are working with our current customers and exploring relationships with new customers to formulate powders and design complex parts to greatly improve performance, significantly reduce production and lead times by eliminating the need for multi-component assemblies.

We feel our molybdenum and tungsten spherical powders, which are optimized for additive manufacturing and engineered for enhanced product performance, will be popular with additive manufacturing techniques such as binder jet, directed energy deposition and powder bed fusion.

The enhanced spherical shape of our powders improves their flowability and gives them a high apparent density in order to meet the stringent purity levels demanded by our customers and their application requirements.

Refractory metals will always be specialized and challenging to work with. H.C. Starck Solutions, with nearly 100 years of experience with refractory metals, is an ideal partner to solve customer problems. Whether it is a complex refractory alloy, powder or a highly complex finished part, H.C. Starck Solutions can help.

Yes, we have been able to develop new materials, processes, and products using additive manufacturing tools, since 2014, when H.C. Starck Solutions' FPR entered into an agreement with Rapid Prototype and Manufacturing (rp+m).

Also, with our rp+m collaboration, we now produce additively manufactured tungsten components for medical imaging and security screening much faster and more efficiently than before. With additive manufacturing, we can rapidly develop prototype products that extend to production level volumes in record time.

Due to their partnership with rp+m, H.C. Starck Solutions can also provide 3D printed components as well as the raw materials for additive manufacturing.

More information can be found on our website. Our brochures “H.C. Starck Solutions and rp+m to develop 3D Printed Products” and “H.C. Starck Solutions’ Refractory Metal Powders for Additive Manufacturing” can be downloaded using the below link.

Download the Brochure for More Information

The H.C. Starck Group is a leading global supplier of technology metals and advanced ceramics. The company operates modern manufacturing facilities in Europe, America, and Asia and serves growing industries such as the electronics, chemicals, automotive, medical technology, aerospace, energy technology, and environmental technology industries, as well as engineering companies and tool manufacturers.

On December 31, 2017, the H.C. Starck Group had 2,600 employees in the United States, Canada, Great Britain, Germany, China, Japan, and Thailand.

H.C. Starck’s products are predominantly based on technology metals: Tantalum, Niobium, Tungsten, and Molybdenum.

The Fabricated Products Division converts technology metal powders into customized semi-finished and finished products through pressing, sintering, rolling, melting and thermo-mechanical processing and surface treatment.

The Tungsten Division provides high performance products for the mechanical engineering and tool making, automotive and energy industry, aviation industry, and the chemical industry, for example:

The Advanced Ceramic Components (CER) Division manufactures specialized technical ceramic parts and films. CER produces engineering parts such as sealing rings, functional parts including fuel cells for solid oxide fuel cell (SOFC) systems and products for dental applications as well as for armor and wear protection. Furthermore, CER focuses on technological developments to expand the portfolio toward product applications in the semiconductor industry.

In 2018 H.C. Starck sold the division Surface Technology & Ceramic Powders to the Swedish Höganäs Group, effective March 1st and the division Tantalum and Niobium to the JX Nippon Mining & Metals Group, effective July 1st.

The group is led by a two-member Executive Board: Dr. Jens Knöll (Chairman of the Executive Board), Dr. Jan Lösch (Member of the Executive Board).

H.C. Starck was founded in Berlin in 1920. Since 2007, the company is owned by financial investors Advent International and The Carlyle Group.

H.C. Starck is registered in Goslar (Germany) and the Group’s headquarters is located in Munich (Germany).

This information has been sourced, reviewed and adapted from materials provided by H.C. Starck Solutions.

For more information on this source, please visit H.C. Starck Solutions.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.

Jake graduated from the University of Manchester with an integrated masters in Chemistry with honours. Due to his two left hands the practical side of science never appealed to him, instead he focused his studies on the field of science communication. His degree, combined with his previous experience in the promotion and marketing of events, meant a career in science marketing was a no-brainer. In his spare time Jake enjoys keeping up with new music, reading anything he can get his hands on and going on the occasional run.

Please use one of the following formats to cite this article in your essay, paper or report:

H.C. Starck Solutions. (2023, April 21). Additive Manufacturing - Technology Metals for Industrial 3D Printing. AZoM. Retrieved on October 19, 2023 from https://www.azom.com/article.aspx?ArticleID=13410.

H.C. Starck Solutions. "Additive Manufacturing - Technology Metals for Industrial 3D Printing". AZoM. 19 October 2023. <https://www.azom.com/article.aspx?ArticleID=13410>.

H.C. Starck Solutions. "Additive Manufacturing - Technology Metals for Industrial 3D Printing". AZoM. https://www.azom.com/article.aspx?ArticleID=13410. (accessed October 19, 2023).

H.C. Starck Solutions. 2023. Additive Manufacturing - Technology Metals for Industrial 3D Printing. AZoM, viewed 19 October 2023, https://www.azom.com/article.aspx?ArticleID=13410.

Do you have a review, update or anything you would like to add to this article?

In this interview, AZoM speaks to LECO's Andrew Storey about glow discharge spectrometry and the opportunities offered by LECO's GDS950.

At the Advanced Materials Show 2023, AZoM sat down with Tom Warwick, Director and one of the two Founders of Blue Scientific, to discuss the rapid growth of the business and its ambitions for the future.

Phil Levesque & Charlie Pryor

In this interview, AZoM speaks to Instron's Phil Levesque and Charles Pryor about the importance of mechanical testing for electric vehicle batteries.

The XRF Scientific Orbis laboratory jaw crusher range features dual-action fine crushers, with jaw efficiency allowing samples to be reduced by up to 55 times their original size.

The DynaPro Zetastar Static Light Scattering Detector performs simultaneous dynamic and static light scattering or dynamic and electrophoretic light scattering (DLS/SLS/ELS) measurements all within one instrument.

The Thermo Scientific™ ARL iSpark™ Plus Series OES Metal Analyzer is the perfect instrument for every process from routine elemental analysis to heavy-duty metals R&D.

The global semiconductor market has entered an exciting period. Demand for chip technology is both driving the industry as well as hindering it, with current chip shortages predicted to last for some time. Current trends will likely shape the future of the industry, which is set to continue to show

The primary distinction between graphene-based batteries and solid-state batteries lies in the composition of either electrode. Although the cathode is commonly changed, carbon allotropes can also be employed in fabricating anodes.

In recent years, the IoT is rapidly being introduced into almost all sectors, but it has particular importance in the EV industry.

AZoM.com - An AZoNetwork Site

99.95% Bismuth Ingot Owned and operated by AZoNetwork, © 2000-2023