ContiTech air spring systems is focusing its presence at the Heavy Duty Aftermarket Week (HDAW) in Las Vegas on its service, quality and product designs for the air spring replacement market. Related Articles - Trailer orders drop significantly in November - NACFE identifies methods to reduce freight emissions in intermodal - Peterbilt expands collision mitigation features for Model 579

“For us, the Heavy Duty Aftermarket Week is one of the most important events worldwide and is the ideal meeting place for in-depth discussions with our customers in the NAFTA region,” said Alexander Papadimitriou, head of the ContiTech Air Spring Systems segment. Air Lift 60732 1000 Series Rear Air Spring Kit

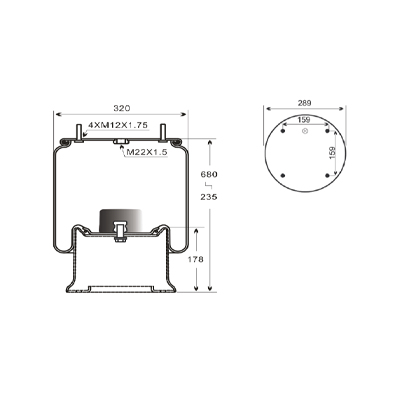

According to the company, ContiTech Air Spring Systems is aiming to continue its successful growth in the NAFTA region with high standards for quality and short delivery times for its air springs. After 40 years in the USA, ContiTech has over 800 designs in its aftermarket product range for the NAFTA market.

“We cover nearly every use in the North American replacement market,” said John Hilkirk, product manager for ContiTech Air Spring Systems Aftermarket in the NAFTA region. “Customers benefit from the quick turnaround that we ensure as our production facility is located in the NAFTA region. This has a considerable advantage, as each customer location in the NAFTA region can be reached within just a few days.”

Customers in the replacement market are benefiting from the development expertise that ContiTech Air Spring Systems has built up in close collaboration with vehicle manufacturers and is bringing new product solutions to the industry. “Our versatile products provide attractive solutions,” said Hilkirk, “and their optimal price/performance ratio impresses every market segment.”

Volvo Trucks places safety and sustainability at the forefront of every decision we make. It is our responsibility at Volvo Trucks to protect and preserve the finite resources of our planet. While making our business environmentally and financially sustainable, we will, together with our customers, leave a better world to our future generations.

The center now has 80 engineers and roughly three dozen administrative employees in a facility expanded to more than 25,500 square feet.

Bendix Commercial Vehicle Systems is celebrating five years of its Technical Center in Monterrey, Mexico. Having opened in 2018 with 34 employees – 32 of them engineers – in a 7,800-square-foot space, the center now has 80 engineers and roughly three dozen administrative employees in a facility expanded to more than 25,500 square feet, Bendix says.

FTR’s numbers have Class 8 orders for October at 28,000 units.

These vehicles will be utilized to pick up parts from various supplier locations in the Pacific Northwest and deliver them to DTNA’s consolidation center in Portland.

Peterbilt presented TMC Transportation, Inc. with the keys to the Model 579 at the Denton plant.

Now we come to the answer to the question that started it all: How fuel efficient can a new truck driver be? Related Articles – ACT Research: Used truck prices stabilize in October – Five truck trend takeaways from November – FTR Shippers Conditions Index shows positive readings in September as diesel prices fall As

Year-to-date, cumulative new business volume was up 0.7% compared to 2022.

October net orders, at 35,300 units, were 26% higher year-over-year, and 4,000 units more than were booked in September.

The outlook is for consistently negative readings for the TCI in 2024.

The battle to earn the CDL is over, but the fight to crown a fuel efficiency champion is just getting started.

Air Spring Contitech Truck industry content for fleet owners and managers