Synopsis: Roofer Andrew Grace discusses working with copper, from the specifics of the material and its aging and handling processes to the step-by-step installation of a field-locked standing-seam copper roof over a bay window.

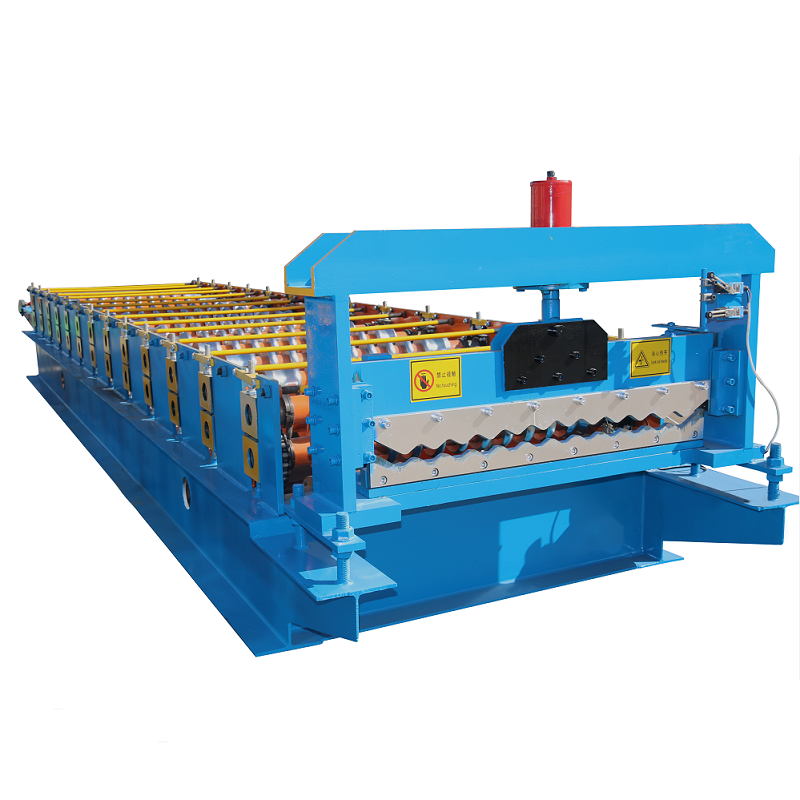

Snap-lock standing-seam metal panels like those we commonly use on homes and outbuildings have, as the name implies, snap-together standing seams that are put together without tools up on the roof. Because snap-lock panels are premade and can’t be field-seamed, they require sealants for detailing. Sealants have improved over the years, but even the best will fail decades before a metal roof reaches its minimum 100-year lifespan. Sheet Cut-To-Length Machine

To eliminate sealant-reliant details and give our clients a longer-lasting, more resilient roof, we started to incorporate traditional field-lock flashing details into our snap-lock standing-seam roofs a few years ago. Field-lock seams don’t snap together—the panels are fastened to the roof with clips and are rolled or folded together to create a waterproof joint that joins panels together. The transitions are also less bulky and better-looking than those that aren’t field-seamed.

Copper as a roofing material has a long history; early examples include the Lowa Maha Paya Temple in Sri Lanka in the 3rd Century BC and the Pantheon built by the ancient Romans. Further examples span centuries and the entire globe. Aged copper’s distinctive verdigris finish makes it recognizable even to those without an interest in architecture. My crew and I find copper work satisfying because the skills, tools, and training it takes to be proficient puts us in a small group of specialized contractors who do this work.

Flat copper for roofing and flashing used to be a standard item at my local lumberyards and roofing suppliers, but more recently it’s been harder to find as global demand has made it increasingly scarce. In addition, roofers have largely turned to cheaper materials like coated steel and coated and plain aluminum for mainstream roofing and flashing work. Compared to aluminum and steel, copper is far more malleable, and can be formed into curves and other complex shapes without cracking or tearing as it’s manipulated.

Copper is sold in sheets, small rolls, and large rolls. Both soft and half-hard copper are available at specialty suppliers; half-hard is the better material for valleys, flashing details, and hip and ridge caps. Soft copper is a better choice for small curved flashing and other areas that require an easy-to-form material. The 2-ft. wide, 1000-lb. rolls I buy annually are delivered on a tractor trailer, and I unload the roll from the truck with my skid steer. Copper prices follow the commodities market and at the time of writing is selling for about $5 per lb.

The distinctive green finish you see on copper often takes years or decades to develop. Before it gets there, copper goes from a shiny penny stage to blotchy light and dark browns, to fully brown, before a gradual switch to its final dusty green. I make sure clients know that the aging process takes a long time and the transition can be blotchy and unpredictable. We wear gloves to prevent obvious hand prints from showing up in the finished work. The marks left by finger- and handprints won’t harm the material, but they can be obvious and unsightly until the copper takes on its dark brown color that obscures them.

Field-lock seams come in two flavors: single-lock and double-lock. As you might guess, single-lock panels are rolled together once; double-lock twice. A double-lock roof can be watertight at very low slopes (1:12) without any sealants. The magic of the field lock is the pocket fold. A pocket fold allows you to form one panel to meet two planes without the pinhole created by lapping panels.

Although field-lock panels can be roll-formed for larger projects by metal roofing producers, the short panels needed for this small elevation can be made on-site with a sheet-metal brake. Since we use copper for our flashing on all our roofs and most of our siding projects, I buy a master coil of 16-oz. copper every year. (Copper sheet is sold by weight; 16-oz. copper weighs 16 oz. per sq. ft.)

As you might imagine, field-seaming is labor-intensive work, which is why most clients will save a project like this for an elevation that needs something special (and also why we use a mix of snap-lock and field-seamed details on larger projects). This fully field-seamed three-sided bay-window roof took two skilled roofers almost four days to finish. Almost all of the tools you see in this feature, excepting the few I found at yard sales, can be found at John Stortz & Son, which is pretty much the only game in town for some of the more specialized tools. We’ve spent about $3000 to $4000 in metal roofing tools that make it easier to do the work and that make the finished product look better.

Working on a project like this this allows us to show off our skills and give our clients a beautiful detail for their home. And it’s even more rewarding to think that in the following centuries, builders and roofers may still be admiring our work on this long-lasting little roof.

For a multiday project like this one, we take the expensive and labor-intensive panels off the roof at the end of the day so they don’t blow away. We hold off on lapping the panels under the water-resistive barrier (WRB) until we’re done, because the panels will be on and off the roof several times before the roof is completed.

Andrew Grace is a builder and roofer in Ligonier, Pa. Photos by Patrick McCombe.

Sign up for eletters today and get the latest how-to from Fine Homebuilding, plus special offers.

A complete resource that includes the best materials and the right techniques to build a sturdy, leak-free, attractive roof on any house

View All Project Guides »

Become a member and get unlimited site access, including the Roofing Project Guide.

Get home building tips, offers, and expert advice in your inbox

© 2024 The Taunton Press, Inc. All rights reserved.

Get home building tips, offers, and expert advice in your inbox

Become a member and get instant access to thousands of videos, how-tos, tool reviews, and design features.

Start your subscription today and save up to 70%

Get complete site access to expert advice, how-to videos, Code Check, and more, plus the print magazine.

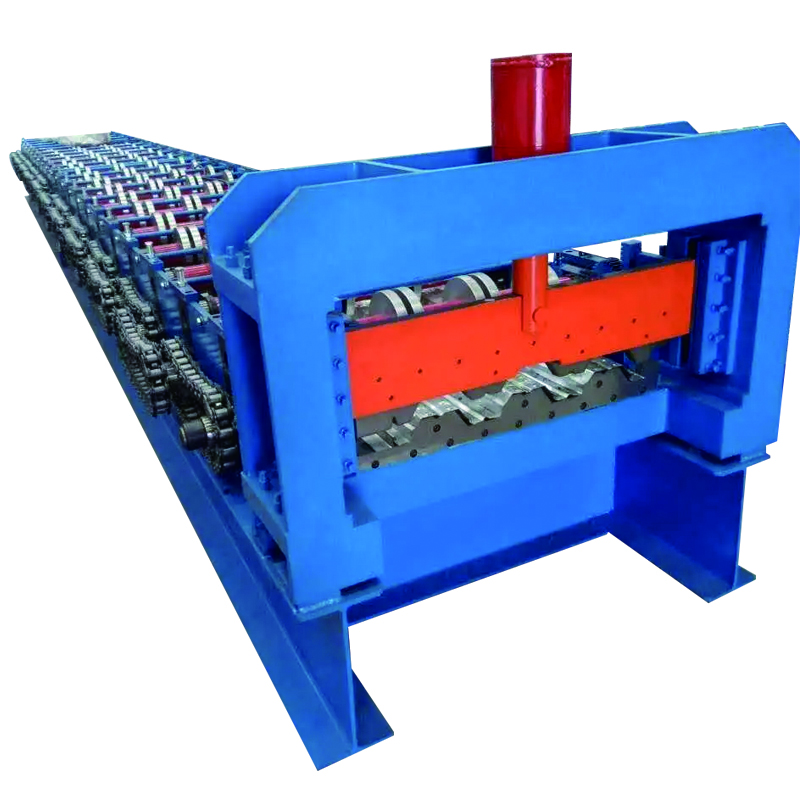

Metal Steel Sheet Decking Floor Production Roll Forming Line Already a member? Log in