02-Jan-2014 - Last updated on 02-Jan-2014 at 13:52 GMT

Related tags Potato chips Pressure Potato chip Deoiling Centrifuge

The method centers on use of low pressure frying and deoiling to reduce the content of oil on a snack food products including potato or tortilla chips and other fried food products, Frito-Lay said.

Processing pressure the crucial detail

The snack player said that differential pressures throughout the processing steps were key to improved oil reduction in the end product.

The patent detailed that potato slices must be fried in hot oil (between 320⁰F and 380⁰F) at atmospheric pressure in a continuous fryer, batch, semi-batch or semi-continuous fryer.

The potato chips are then removed for a deoiling step in a vacuum centrifuge at a lower pressure. It is this lower pressure that is the crucial detail, Frito-Lay explained.

“When food pieces have been fried at atmospheric pressure and then subjected to a low pressure centrifugation step, the oil content of the fried food pieces is dramatically and surprisingly lower than when an atmospheric centrifugation step is used.”

“Without being limited by theory, applicants believe that the vacuum draws oil out from the interior spaces of the potato slices to the surface, thereby allowing the centripetal force exerted on the slices by the centrifuge to remove it from the surface of the potato slices. Additionally, the vacuum maintains a positive pressure differential between the internal spaces of the potato slice to the outside, which resists further oil absorption during the centrifugation step.”

These deoiled potato chips have a mouthfeel similar to chips that have not been deoiled under vacuum conditions, Frito-Lay explained, because oil that was previously trapped inside the fried food is drawn to the surface.

Bigger oil reductions with different pressure

Frito-Lay conducted experiments that showed a significant difference in oil reduction when pressures were altered throughout processing.

It found that processing unwashed chips in a centrifuge at atmospheric pressure, oil content by weight was reduced on average by 7.3%. This figure was more than doubled to 16.8% average oil reduction when the centrifugation system used a pressure lower than atmospheric.

In addition to pressure control, Frito-Lay said that the time the chips are spun inside the vacuum centrifuge and lag time between when the product exits the fryer and enters the vacuum can also impact oil removal.

Frito-Lay said the removing and transferring steps in the production line can be heated – as this prevents the chips from cooling and absorbing oil.

Frito-Lay other work on oil reduction

Frito-Lay filed a separate patent at the end of 2012 for a different method it had developed to reduce the oil content of potato chips. The continuous-frying process that uses changing temperatures can reduce oil content by up to one-third, the snack major claimed.

Copyright - Unless otherwise stated all contents of this web site are © 2024 - William Reed Ltd - All Rights Reserved - Full details for the use of materials on this site can be found in the Terms & Conditions

Related topics Processing & Packaging Snacks PepsiCo Processing Equipment & Systems, Automation, Control

Content provided by QAD Redzone | 13-Oct-2023 | White Paper

On average, manufacturers in this QAD Redzone exclusive study achieved productivity increases that allowed them to make 5 days of product in just 4 days....

Content provided by Angel Yeast – Yeast and Baking Ingredients | 10-Oct-2023 | White Paper

An innovative solution used to slow down the aging process, extend the shelf life of bread, and solve the problem of "flavor loss"!

Content provided by TELUS Agriculture & Consumer Goods | 20-Mar-2023 | White Paper

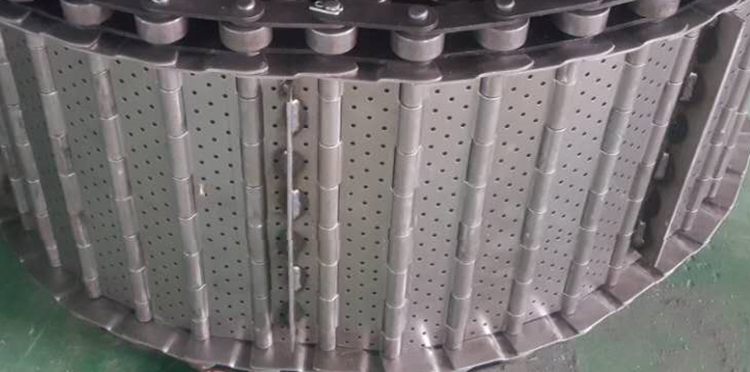

Drag Chain Conveyor Right now the food industry is battling twin challenges – to produce more food, while improving environmental impact. With 60-70% of the world's ecosystems...