October 13, 2023 By MDO Contributors Network

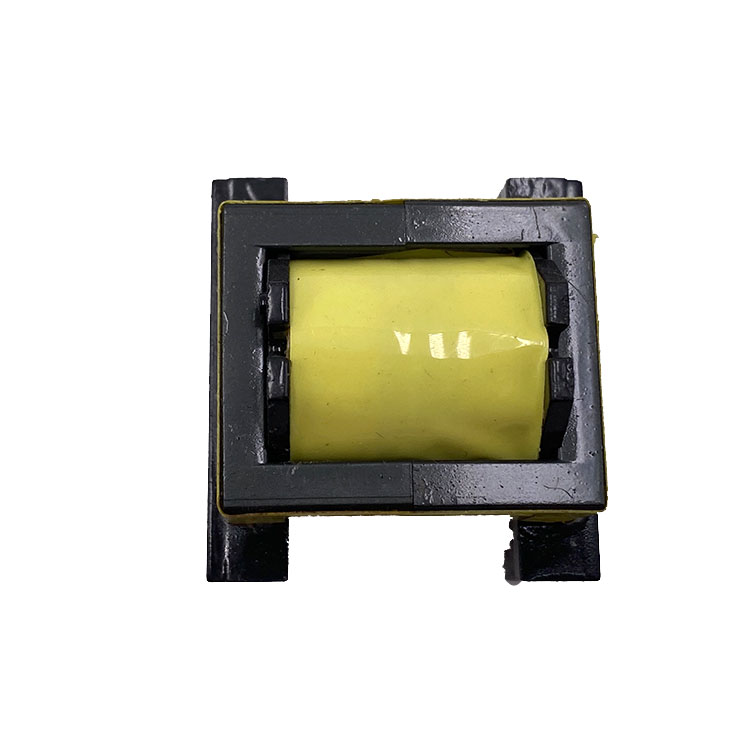

By Trent Birkholz and Sam Puent, Intricon Air Core Coil Inductor

An electromagnetic sensor in a catheter and micro-coils on a dime for scale [Illustration courtesy of Intricon]

As EMN gains traction, the importance of electromagnetic sensors in medical devices is clear. Choosing a sensor that optimizes performance, cost, and manufacturability is paramount, so manufacturers need to carefully evaluate which features their surgical navigation systems demand to achieve clinical and market success.

This article details the advantages of EMN for surgical navigation and explores considerations for optimizing sensor performance, cost, and manufacturability.

Those advantages have driven significant growth as EMN becomes more widely adopted across clinical practice areas such as otolaryngology, oncology, urology, pulmonology, neurology, cardiology, and robotic surgery. In fact, the EMN market is projected to grow at a rate nearly three times that of fluoroscopy through 2030.

Electromagnetic sensor micro-coils on a dime for scale [Illustration courtesy of Intricon]

Number of sensors: Consider how many sensors are required to visualize everything needed during a given procedure. For example, a second sensor can grant views of rotation in addition to the X, Y, and Z aspects of device position. The number of sensors on a device ultimately affects design, manufacturing processes, and cost.

Placement and form factor: In many cases, sensors are placed within the tip of a device, such as a catheter — but that can take up a lot of real estate. Sensors can be custom-designed with form factors that fit within space constraints.

Sensor integration: Sensor components can be designed to fit into a device or, alternatively, sensors can be constructed onto sub-components within a device, optimizing use of space. Integrating sensors into your assembly maintains performance standards while reducing overall real estate.

Sensor design: Various design levers can be manipulated to optimize electrical performance and sensitivity for a given application. Wire size, core material, and number of wraps all affect performance. Length, diameter, shape, and core geometry can be independently adjusted to customize a sensor. Note that solid core sensors are stronger and offer greater sensitivity than hollow-core sensors. Dual-core sensors are possible, but more complicated to manufacture.

Trent Birkholz is VP of development at Intricon.

Off-the-shelf sensors aren’t always the best option, but in some cases, they offer advantages such as lower cost, immediate availability, and rapid turnaround. They’re ideal for prototypes, and you can often apply relatively minimal modifications to make an off-the-shelf sensor fit your design. Thus, off-the-shelf sensors can be a good choice, given the ubiquitous nature of cost pressures across medical devices and practices.

Custom sensors allow you to address unique challenges for specific applications. Unlike off-the-shelf sensors, you can integrate custom sensors into an eloquent design that saves space and increases functionality. Custom sensors can also be built with specialized attachments and designed for manufacturability to accelerate time to market.

Whether your application calls for an off-the-shelf or custom sensor, choose a vendor willing to work as an extension of your design team, test your designs, and make recommendations and iterations to improve performance, manufacturability, and costs. Keep in mind that a sensor could work perfectly in a clean environment but underperform in the surgical suite. In one example, a company didn’t discover it had bad data until it entered the design validation stage, forcing a complete redesign. A good partner could have helped the company avoid the costly delay.

Intricon Product Development Engineering Manager Sam Puent

The opinions expressed in this blog post are the author’s only and do not necessarily reflect those of Medical Design & Outsourcing or its employees.

Subscribe to Medical Design & Outsourcing. Bookmark, share and interact with the leading medical design engineering magazine today.

DeviceTalks is a conversation among medical technology leaders. It's events, podcasts, webinars and one-on-one exchanges of ideas & insights.